Precast concrete - Future of next Generation

Precast concrete: construction technology includes various precast products such as walls, beams, slabs, columns, stairs, landings and some customized elements that have been certified and designed for the stability, durability and structural integrity of the building.

Manufacturer of precast construction purchase raw material cheaper compared to retail market. Also mold and machinery can be use regularly. This type of manufacturer think that more cheaper, than contract with transporter makes product more cheaper due to bulk orders.

Precast construction at manufacturing unit gives many advantages like cost cutting, more strong because it can be cast on ground or easiest place with proper required curing. supervision of expertise. so, strength and quality can be increase with life span of construction.

Precast concrete products prepare at manufacturing unit is beneficial because it can prepare at controlled environment. So, production capacity will not decrease. it helps to construction timeline to completion on time. Completion of project on or before time saves labor, manpower and general transportation and site experiences.

As weather condition not affect to production, it will help project to timely deliver. And also minimize the installation time compared to cast-in-site.

Generally, 5-10% concrete goes waste at site construction due to lake of proper supervision and other lazy issues. As precast concrete products casting at manufacturing unit will minimize the wastage of concrete material because of proper supervision.

"According to NCPA guide to precast concrete, compared to traditional construction process, precast concrete can reduce floor depth up-to 4 inches. in 60 story building construction, You will save 2 stories construction cost. around 3.5% cost saving

Labor work also minimized at site after precast concrete widely using by construction industries.

Precast concrete products

Precast compound wall

Precast compound wall is used to secure land or ground or property.

Precast compound wall make using fill precast concrete into reusable mould and reinforced with HT steel and give stress to the HT wires if material pre-stressed material is being prepared. After that fill concrete into reusable moulds.

Precast compound wall prepares from the precast panel and H/I section column.

Size of precast panel and column may change on requirement and structural design.

It is also known as Precast concrete wall, RCC Wall, Cement Boundary walls, Readymade walls

Retaining wall

Retaining walls are using to retain earth filling or soil filling load

Precast Partition

To divide the Building or make partitions of the big room or floor, Precast partition is the best and fast solution for construction industries.

Precast Beam column

Precast columns are uses various places. Building column, precast concrete wall. it is the best solution for underwater constriction or bridges construct on water. Precast columns are easily set into this type of situation and work makes very easy.

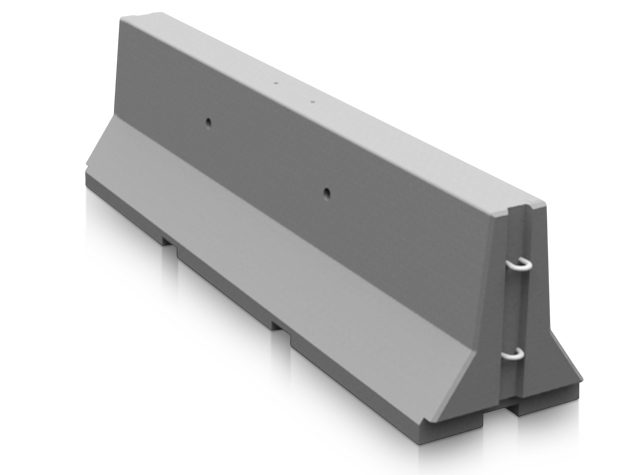

Precast barrier

Precast barriers are used to side of the roads and middle line of the road to divide

Precast Benches

From precast concrete, Precast benches can be design and prepare with variety of designs and specifications. concrete can variety of options and design options

Over-bridge partition

Over bridge’s sides are covered with this type of partitions

Curb stones

Curbstones are used to prepare road or footpath. design and size and design may change depending upon mould design. It can be use for Garden curbing

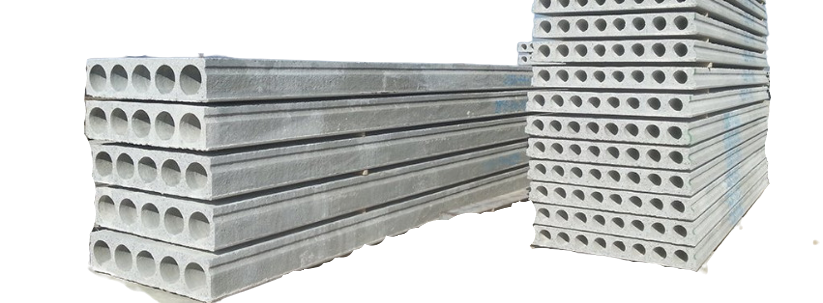

Precast Panels

Precast panels are used in partition wall and other Precast compound wall. it can be use in warehouse shade partitions, Building partitions, Buildings, Compound wall and many other places. size of panel may change depending upon site requirements

.